The role of truss manipulator in intelligent bar warehouse

The role of truss manipulator in intelligent bar warehouse

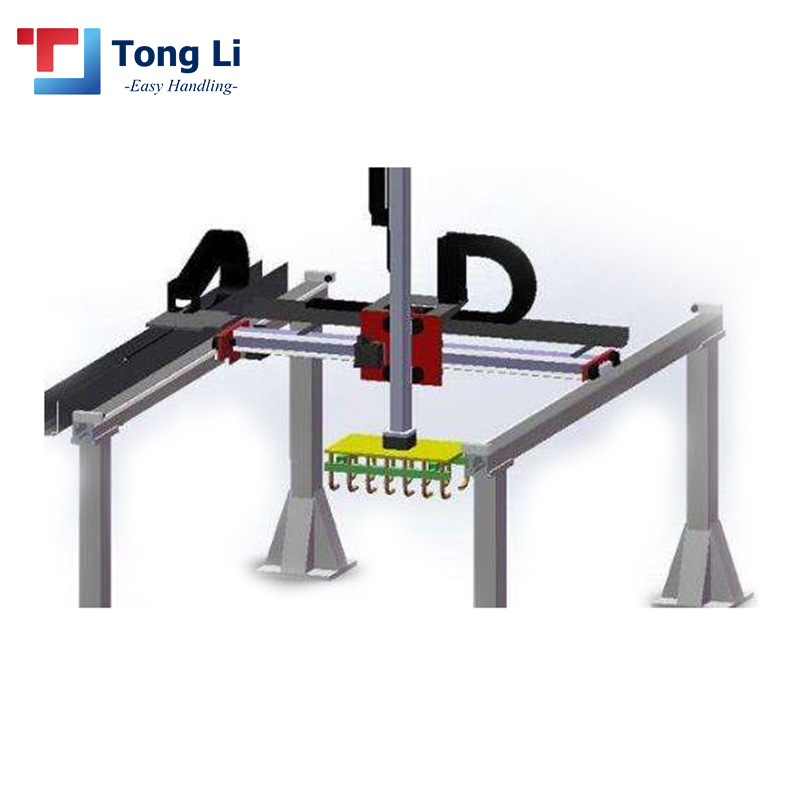

Warehousing operation: Take over the bars from the external conveying equipment and place them on the designated cargo position.

Outbound operation: According to the system instructions, take out the bars from the designated cargo position and transport them to the production line or other designated locations.

Handling operation: Carry out the handling and transfer of bars in the vertical warehouse.

Cutting operation: Some truss manipulators can also be equipped with cutting devices to achieve online cutting of bars.

Collaboration between truss manipulators and intelligent bar warehouses

Precise docking: The truss manipulators are precisely docked with the vertical warehouse shelves, conveying systems and other equipment to ensure smooth material handling.

Data interaction: The truss manipulators interact with the control system for data to achieve real-time positioning and control.

Flexible production: Through programming, the truss manipulators can adapt to bars of different sizes and weights to achieve flexible production.