Welcome to our websites!

News

-

Components of pneumatic manipulator and its role

The use of pneumatic manipulator is becoming more and more widespread, but do you know what its components are? Do you know what are their roles? Below Tongli will explore this industrial robot with you. Structure of the parts of pneumatic manipulator The industrial robo...Read more -

The introduction of air manipulator

Manipulator With Air Shaft driven by air actuators have been developed as a multifunctional final actuator for material handling systems. The arm consists of a pneumatic hand and a gas wrist. The industry robot can grip a variety of objects without force sensors or feedb...Read more -

Types and safety of Pneumatic manipulator

Pneumatic manipulator are ideal for the efficient and secure grabbing and placement of items of all shapes and sizes. The gripping weight varies between 10 and 800 kg. Tongli will go into further depth about it. The types of Pneumatic manipulator 1.Classified by structure: Pneumatic manipulator a...Read more -

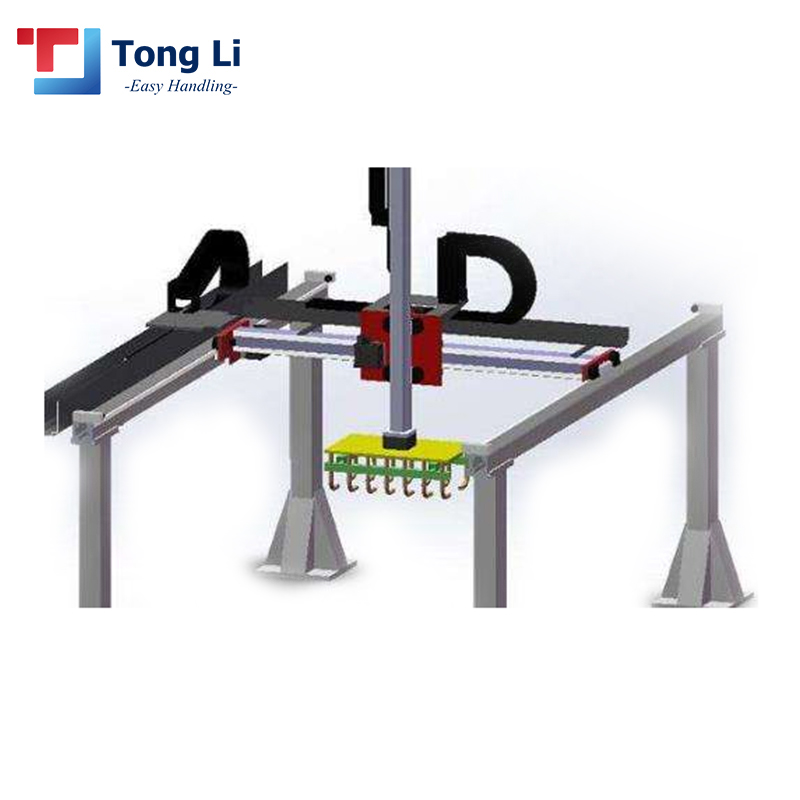

Nine tips you need to know to solve the trouble of truss manipulator

In the process of daily use of truss manipulator, you may encounter different problems, which can cause some unnecessary loss to the enterprise. So how to avoid and solve these problems? Here Tongli will share the solution skills with you. 1.Troubleshooting, debugging Fo...Read more -

Truss manipulator maintenance knowledge you must know

The maintenance cycle of truss manipulator is necessary to adjust and replace the parts that can be expected to change with time or use, which is called "standard maintenance". The purpose is to keep the robot performance in t...Read more -

Introduction of Manipulator

A manipulator is an automatic operating device that can imitate certain movement functions of the human hand and arm to grasp and carry objects or manipulate tools according to a fixed program. It is characterized by the ability to be programmed to perform a variety of e...Read more -

How industrial Manipulator work and what they do

A manipulator is a multifunctional machine that can automate positioning control and can be reprogrammed to change. It has multiple degrees of freedom and can be used to move objects to perform work in a variety of different environments. Industrial manipulators are a new technology in the field ...Read more -

Development History Of Industrial Manipulators

With the continuous advancement of technologies, the biggest difference between the industrial manipulator arms and human arms is the flexibility and endurance. That is, the biggest advantage of the manipulator is that it can perform the same movement repeatedly under no...Read more -

Safety First! Top Tips To Prevent Industrial Robot Hazards

Global sales of industrial robot manipulator has seen exponential growth in just a few years, among which China has been the world’s largest consumer of industrial robots since 2013, according for more than one-third of global sales. An industrial robot can be a “cold-bl...Read more -

5 Factors To Be Considered When Choosing An Industrial Manipulator

An industrial manipulator, the equipment for facilitating handling operations, can pick up and manipulate heavy loads, enabling the user to carry out fast, convenient and safe handling. In order to choose the most suitable industrial manipulator for your application, Ton...Read more -

Maintenance Tips To Extend The Life Of Your Industrial Manipulator

As is known to all, industrial manipulator has been widely used in the manufacturing fields to achieve automated production operations, improving factory production efficiency while also ensuring the stability of product quality. However, many factories neglect the manag...Read more -

Technical Requirements For Pneumatic Components Of Power Manipulator Servo System

Flexible power-assisted manipulator is a novel kind of assistance equipment that helps save labor for material handling and installation. Making use of the principle of force balance skillfully, the power manipulator enables the operator to push and pull the heavy object...Read more