Factory making Stacking Manipulator - Manipulator With Suction Cup – Tongli

Factory making Stacking Manipulator - Manipulator With Suction Cup – Tongli Detail:

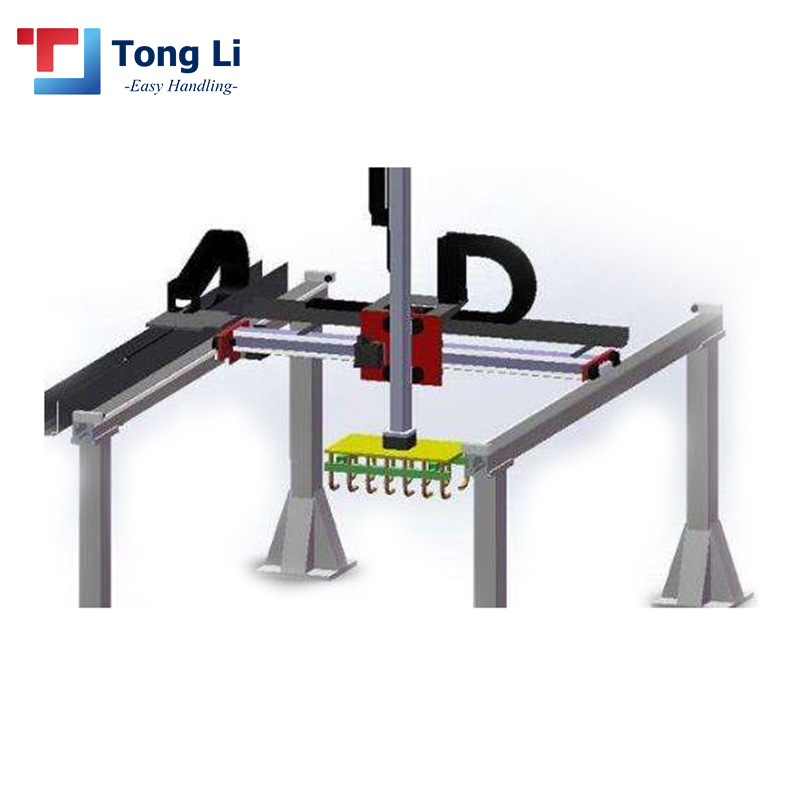

Tongli manipulators with suction cup are widely used for non-destructive handling of various plates, including corrosion resistant plates, aluminium plates, titanium plates, composite panels, etc.

They are also widely used for laser cutting machine, plasma cutting machine, water-jet cutting machine, numerical control press, etc.

The equipment suction cup made of cast aluminum with one-time high-pressure die-casting molding, have characteristics of light weight, high strength, detachable suction cup rubber, easy to replace, environmentally friendly and have high cost-effective.

Brand-new pure pneumatic system, no need to connect electricity, no charge, pneumatic lifting, pneumatic adsorption, economical and applicable

Sucker position can be adjusted to meet dimensional change of different plates.

Suction-cup manipulators are good at grasping objects with flat and regular surfaces, so they are used in logistics, production and sorting, food industry, automobile production, glass handling, sheet metal handling and other fields, and their number and types are the largest in grabbing manipulators.

Let’s classify according to the purpose of realization and take a look at the application of suction cup manipulator:

1.Item Grabbing

It is mostly used for lifting and transferring heavy objects.

Such as carton stacking and parcel grabbing in the logistics industry;

Such as the lifting and grabbing of parts and products in the mechanical and chemical industry;

Such as glass, sheet metal parts grabbing and turning;

Such as airport baggage transfer and handling;

Such as the promotion and transfer of large parts.

These manipulators are simple in structure. Most of them are flexible arms with suction cups. They reach designated items through human operation, and there is almost no control system. The price is cheap, and the application is widespread. It is mainly to replace manual handling and lift heavy objects.

A slightly more complicated machine with less degrees of freedom can realize the overturning of the grabbed items.

2. Automatic Palletizing

It is mostly used in logistics, warehousing, and ports. It is used for automatic grabbing of materials and fixed-point stacking functions.

For example, sorting and palletizing in the logistics industry and production enterprises;

For example, storage, storage of goods in the port;

This type of manipulator has a robotic arm that can move automatically, but most of them have low degrees of freedom and achieve relatively simple motion. The position positioning accuracy is not high, the program and control system are relatively simple, and the actuator is not a precision device.

T3. Precise Capture And Distribution

In some fields, manipulators are required to achieve precise grasping and precise placement of items, such as the food, medical, and electronic industries. These industries have high requirements for cleanliness, and suction cup manipulators are widely used. In order to achieve precise positioning, multi-degree-of-freedom robotic arms are often used.

The degree of freedom of the manipulator, the structure is also multiple and diverse.

The actuator of the suction cup manipulator is a vacuum suction cup, which can grasp a wide range of items. The vacuum suction cup has high suction power and is clean and hygienic. It is favored by some industries that require cleanliness. The manipulator can be equipped with various forms and structures. It can be an uncontrolled human-driven flexible arm, a low-degree-of-freedom serial manipulator, or a high-degree-of-freedom parallel manipulator. The matching is more flexible. Based on the advantages of the suction cup manipulator, this type of manipulator accounts for a very large proportion of the manipulator market.

|

Equipment model |

TLJXS-YB-50 |

TLJXS-YB-100 |

TLJXS-YB-200 |

TLJXS-YB-300 |

|

Capacity |

50kg |

100kg |

200kg |

300kg |

|

Working radius |

2500mm |

2500mm |

2500mm |

2500mm |

|

Lifting height |

1500mm |

1500mm |

1500mm |

1500mm |

|

Air pressure |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

0.5-0.8Mpa |

|

Rotation Angle A |

360° |

360° |

360° |

360° |

|

Rotation Angle B |

300° |

300° |

300° |

300° |

|

Rotation Angle C |

360° |

360° |

360° |

360° |

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Factory making Stacking Manipulator - Manipulator With Suction Cup – Tongli , The product will supply to all over the world, such as: Nigeria, Ecuador, Namibia, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!